Director: Shili Xu

https://imaging.crump.ucla.edu/

The Crump Institute's Preclinical Imaging Technology Center provides state-of-the-art in vivo molecular imaging technologies and related services to faculty, staff and students at UCLA. The Center functions both as a laboratory facility for imaging research and development, and as a shared preclinical imaging resource for researchers across various disciplines on campus. As a world leader in molecular imaging, the Center aims to connect state-of-the-art technologies and imaging expertise with in vivo biological applications, to allow real-time, quantitative measurement of health and disease.

The Imaging Center offers a variety of molecular imaging services including:

In vivo imaging systems include:

Companion PET tracer radiochemistry and radiolabeling services and facilities are available in-house. Adjacent to the Imaging Center is a barrier facility for housing animals before and after imaging with biosafety cabinets for animal procedures. The facility is fully certified for animal, radiation, laboratory, biological (BSL2) and chemical safety procedures.

View Full Size Image | Visit the Website

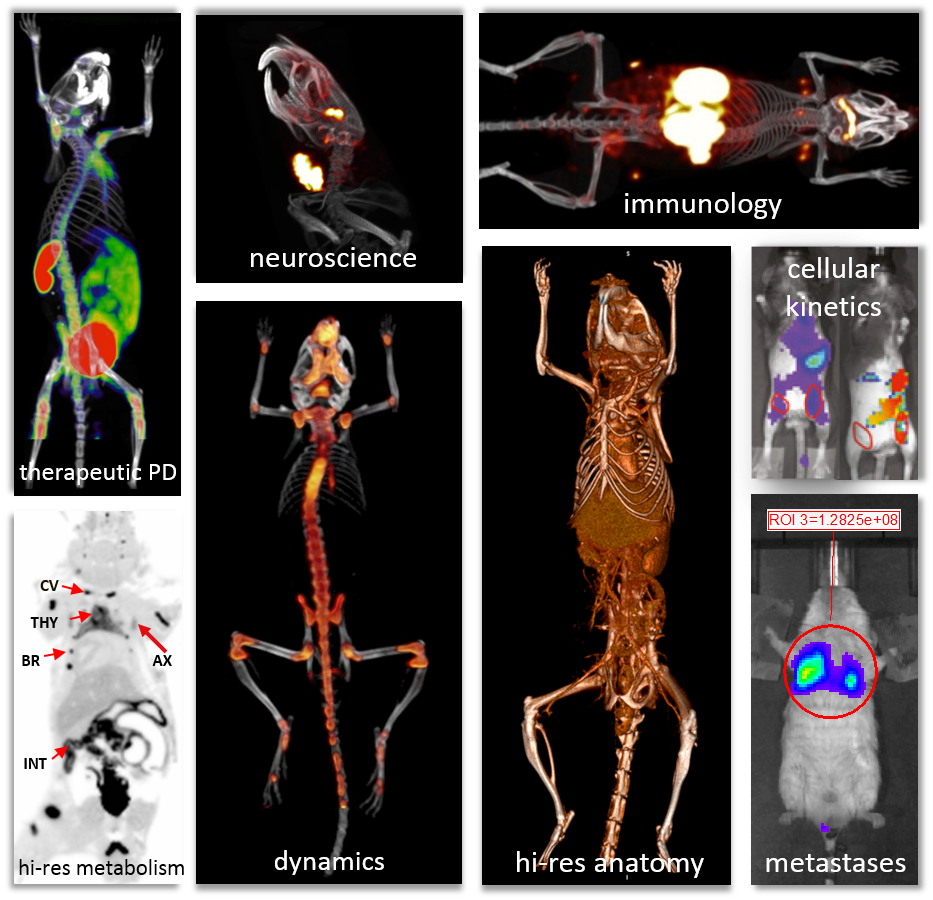

Figure 1: Examples of multimodality in vivo imaging capabilities and applications at the Imaging Center.

Figure 2: State-of-the-art preclinical imaging and companion technologies available for all users to study biological systems, from cells to tissues to whole body.

Director: Michael van Dam

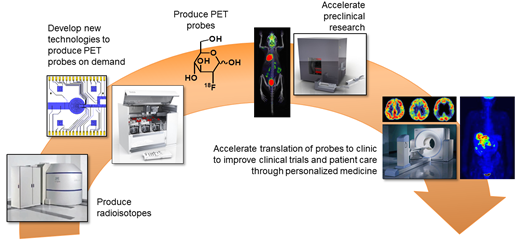

The purpose of the Cyclotron and Radiochemistry Technology Center is to facilitate the development of new radiochemistry methodologies and technologies as well as to provide routine production of standard PET tracers for research work by UCLA or outside investigators in the Preclinical Imaging Technology Center. Probes currently available on a routine basis include: [18F]FDG, [18F]FLT, [18F]FHBG, [18F]SFB, [18F]FNB, [18F]FMAU and analogs, [18F]FAC and analogs, [18F]Fallypride, [18F]FDHT, [18F]DFA, [18F]F-AraG, and this list is expected to grow. In addition, the center is part of the discovery process in collaborations to develop novel PET imaging probes and assays.

The technology center consists of three major components: (i) cyclotron, (ii) radiochemistry laboratory, and (iii) analytical laboratory. The cyclotron (Siemens RDS 111) is capable of producing commonly used PET radioisotopes such as fluorine-18. Collaboration with the UCLA Biomedical Cyclotron Facility provides access to another two cyclotrons (Siemens RDS 112). Production of PET tracers from these isotopes takes place in the radiochemistry laboratory, equipped with four hot cells (Von Gahlen) and six mini cells (Von Gahlen) that provide shielding for automated and remote-controlled experiments involving high levels of radioactivity. Each hot cell contains a semi-preparative HPLC system (Knauer/Bioscan) and dose calibrator (Capintec CRC-25PET). Currently the cells contain three fully-automated radiosynthesizers (Sofie Biosciences ELIXYS) as well as a variety of custom-built manual and remote-controlled apparatus for development of new technologies and chemistry methodologies. The analytical laboratory is equipped with two analytical HPLC systems, a GC-MS system (Agilent 7890A GC with 5975 MSD GC-MS), and radio-TLC reader (Raytest mini-Gita), etc. for performing analytical tests such as radiochemical purity, radiochemical identity, specific activity, residual solvent content, etc. Collaboration with the UCLA Biomedical Cyclotron Facility provides access to additional analytical equipment for testing the quality of batches of PET tracers. Collaboration with the Crump Preclinical Imaging Technology center provides access to additional analytical tools (e.g., autoradiography and Cerenkov imaging) that are useful in microfluidic radiochemistry technology development. Also associated with the technology center is an organic chemistry laboratory that can be used for preparation of precursors and standards.

Figure 1: Overview of activities and mission of the Crump Cyclotron and Radiochemistry Technology Center. The center is designed to facilitate research into new radiochemistry methodologies and technologies as well as to produce and develop PET imaging probes for research groups at UCLA and elsewhere.

Director: Michael van Dam

To have an impact in the world, promising technologies must eventually move out of the laboratory and into other research labs and clinics. The mission of the Engineering and Prototyping Technology Center is to facilitate transitions from proof-of-concept to working prototype and potentially commercialization. Development of prototype systems enable sharing of new technology between engineers and research scientists, benefiting the science to which the technology is applied, as well as providing feedback for improvements of the technology itself.

The Engineering and Prototyping Technology Center comprises two laboratories in the new Crump Institute space in the CNSI Building: the Mechanical Prototyping Laboratory and the Micro/Nano Fabrication Laboratory. It brings together expertise and state-of-the-art facilities for mechanical design and engineering, precision machining, instrument prototyping and microfluidic device fabrication. In the future, we hope to also establish expertise and facilities for electrical engineering, electronics, control system development and user-interface development. These final stages of prototyping are critical when a system is to be used in a different laboratory.

The mechanical prototyping laboratory contains CAD/CAM workstations, a fully-equipped machine shop, and an assembly and testing area. State-of-the-art equipment includes a CNC milling machine (Haas OM-2A), CNC lathe (Haas HPCL), manual mill (Bridgeport 12BR2J), drill press, vertical band saw, horizontal band saw, and grinder. Machines and tools are available to members of the Crump lnstitute. In the future, the center hopes to provide support staff with expertise in design, drafting, manual machining, and CNC machining to assist with prototyping projects and to provide training in design and machining.

The Micro/Nano Fabrication laboratory is a class 1000 cleanroom located within the CNSI Integrated Systems Nanofabrication Cleanroom (ISNC). The lab contains equipment for microfluidic device fabrication from poly(dimethylsiloxane) (PDMS), glass, and other materials: fume hoods for solvent and acid/base processing, photoresist and PDMS spin coaters (Laurell Technologies WS-650SZ-6NPP/LITE), PDMS vacuum degasser, programmable ovens (Fisher Isotemp), CCD-assisted hole-punching tool, zoom stereomicroscopes (Nikon SMZ-1000), oxygen plasma bonding system (Harrick PDC-001), corona discharge bonding system (Enercon Industries LM4816-11MS-MSA), and a microfluidic chip test station. A biosafety cabinet provides a sterile environment for preparation of microfluidic cell cultures. Extensive additional state-of-the-art facilities for fabrication and characterization of micro- and nano-devices are available on a shared basis in the ISNC, the Nanoelectronics Research Facility (“Nanolab”), and the Nano and Pico Characterization Laboratory (NPL), including photolithography, reactive ion etching, metal deposition, stylus and optical profilometry, scanning electron microscopy, etc. The cleanroom space and equipment are available to members of the Crump Institute.

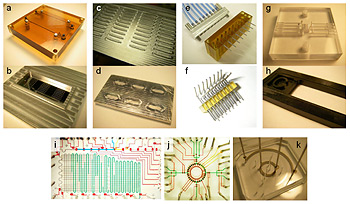

Figure 1: Examples of microfluidic projects from the Engineering and Prototyping Technology Center. (a-b) Lid and base for “injection molding” of PDMS microfluidic devices to control outer dimensions and shape; (c-d) Molds for simple pattern of microchannels machined in aluminum and stainless steel; (e) Quick-disconnect liquid trap interface; (f) Standardized chip connector for rapid and easy chip installation; (g) Polycarbonate manifold for interfacing with a PDMS microfluidic patch-clamp; (h) Microfluidic cell-culture chip holder prototype; (i) PDMS microfluidic chip for screening radiolabeling conditions; (j) PFPE chip for multi-step radiosynthesis; (k) Integrated heater test chip.