Scholars in the START program will engage in a variety of research projects to advance the state of the art in radiochemical synthesizers, PET radiochemistry, and probe development. The following are examples of ongoing and proposed projects:

Sadeghi, van Dam, Keng

Background

Microfluidic synthesizers offer many advantages such as manipulation of small volumes, deterministic flow profiles, enhanced kinetics, short analysis times and the overall reduced footprint of the devices. These devices can be used to achieve rapid synthesis times whilst providing a highly controlled reaction environment which makes them ideal candidates for automated PET radiosynthesis. Traditionally the radiosynthesis proceeds through a series of batch processes conducted sequentially, however the use of flow-through synthesizers can make the process much faster in a smaller form factor. One of the first steps in the synthesis process is the separation of [F-18]fluoride from [O-18]H2O which is usually performed using a combination of ion-exchange cartridges and evaporation. Electrochemical separation of [F-18]fluoride from water for use in radiosynthesis of PET tracers holds many advantages over conventional repeated azeotropic evaporation of water/acetonitrile. These include faster drying, better desolvation and reduction of hydration shell of the adsorbed fluoride ions and ease of integration with emerging miniaturized synthesizers and flow-through microreactors.

Methods

A current working electrochemical flow cell needs to be optimized with the use of microchannel between a platinum electrode and a second electrode formed from interchangeable transition metal foils. The use of novel electrodes in the electrochemical cells will allow application of higher electric fields, faster kinetics and reduces contamination of the released solution. By understanding the electrochemical process, better adsorption/desorption of radioisotope can be achieved with an increased yield and reliability. A miniaturized flow-through synthesizer will be built to reduce the volume of reagents, increase speed and yield compared to traditional synthesis routines. Following success and performance enhancement of the synthesizer, work will focus on integrating on chip separation and solid phase purification under development at the Crump institute.

Outlook

By doing away with azeotropic distillation in a reliable and efficient manner, miniaturized flow-through synthesizers can made that are faster, smaller and potentially have higher yields than traditional approaches to radiotracer synthesis. Fully automated and the flow-through design can also lend itself to easy integration with existing quality control methods for a complete bench-top clinical radiotracer synthesis platform.

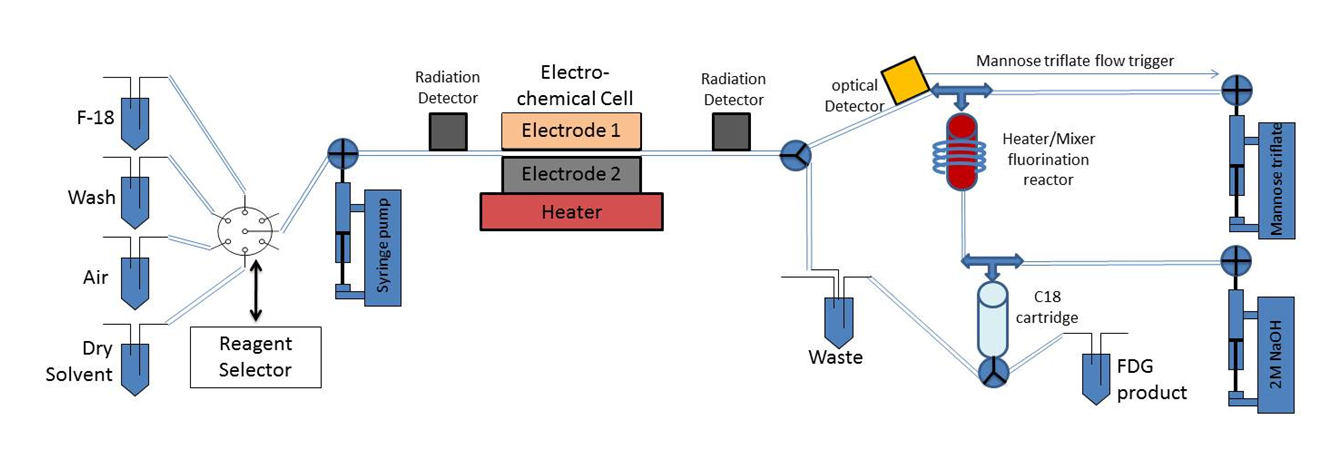

Figure: Aqueous [F-18]fluoride is passed through the electrochemical cell with electric field applied to trap the [F-18]fluoride ions on the anode. The cell is then dried with solvent and gas, and the [F-18]fluoride is released into an anhydrous solvent containing the phase transfer agent under elevated temperature and AC potentials. The released [F-18]fluoride solution is mixed and reacted with mannose triflate in a flow-through reactor at 110°C. [F-18]FTAG is immobilized on a C18 cartridge and separated from the MeCN solvent. It is then released after hydrolysis and conversion to [F-18]FDG by flowing 2M NaOH at room temperature over the cartridge.

Keng, van Dam, Kim, Chatziioannou

Background

Currently, PET tracers are produced in centralized radiopharmacies due to the high cost of infrastructure, equipment and specialized personnel. Decentralized production of 18F-labeled tracers could enhance the diversity of tracers available to researchers and clinicians and increase flexibility of production, but requires new technology. We have developed a novel, compact microfluidic platform based on electrowetting on dielectric (EWOD) that can perform multi-step reactions in microliter-sized droplets. The EWOD microdevice is entirely electronically controlled to perform basic unit operations such as dispensing, transporting, heating and evaporation of organic droplets. In additional to the intrinsic advantages of an all-electronic approach, the hydrophobic layer used in EWOD is also stable against a wide range of temperatures and solvents, making EWOD more suitable for diverse syntheses than many other microfluidic radiosynthesis platforms. We have recently developed a robust synthesis for [F-18]FDG, the most commonly used PET tracer in quantities up to about 1 mCi for preclinical imaging. Our aim is to demonstrate that additional tracers can be synthesized on this platform.

Methods

Several 18F-labeled tracers will be selected based on impact, collaborations, and the ability to synthesize based on operations that are possible in an EWOD chip. Literature syntheses will be adapted to the EWOD platform. Using a variety of analytical tools, including radio-TLC and radio-HPLC of liquid samples from the chip, as well as Cerenkov imaging (realtime imaging of radioactivity within the chip), the synthesis processes will be systematically studied and optimized.

Outlook

Study of additional tracers will demonstrate whether EWOD is capable of robust synthesis of additional tracers.

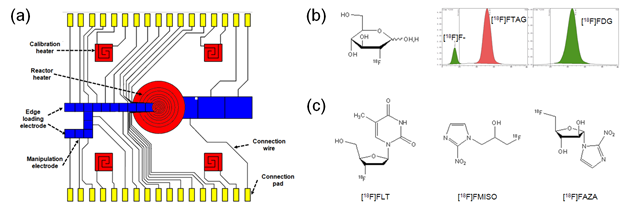

Figure: (a) Schematic of EWOD radiosynthesis chip with heater for evaporations and reactions as well as multiple reagent loading sites. (b) [F-18]FDG structure, and radio-TLC showing good conversion to [F-18]FTAG during fluorination, and showing high purity of [F-18]FDG in purified product. (c) Examples of tracers that could be considered for synthesis on the EWOD platform.

van Dam, Satyamurthy

Background

A number of 18F-radiolabeled nucleoside analogs have been demonstrated to be useful probes for positron emission tomography (PET). For example, 2’-deoxy-2’-[18F]fluoro-5-methyl-1-β-D-arabinofuranosyluracil ([18F]FMAU) and 2’-deoxy-2’-[18F]fluoro-5-ethyl-1-β-D-arabinofuranosyluracil ([18F]FEAU) are established for imaging cell proliferation and herpes simplex virus type 1 thymidine kinase (HSV1-tk) reporter gene expression. In addition, [18F]FAC and its analogs are useful as probes of deoxycytidinekinase (dCK) activity and have potential applications in monitoring lymphoid organs and immune activation, as well as in predicting response to the nucleoside prodrug family of cancer drugs. To meet growing demand for PET tracers in the [18F]FAC family, we are developing an integrated radiosynthesizer uniquely capable of the high-pressure reaction conditions required in this multi-step synthesis. To accelerate development of these tracers into the clinic, we aim to develop an automated synthesis of [18F]FAC on this new platform. Further goals include yield optimization to reduce the starting activity, process optimization to shorten the synthesis time, simplification of reagent handling, and simplification of purification.

Methods

This project will involve translation of the current manually-controlled synthesis to the automated platform followed by multiple validation runs to verify repeatability of the synthesis. Optimization will begin with a variety of characterization studies to investigate: (i) radioactivity loss at various stages of the synthesis, (ii) temperature profiling of each heating and cooling step, (iii) study of storage and stability of sensitive reagents that are currently added manually, etc. Once the most promising directions are identified, experiments will be conducted to determine the impact of individual changes on the synthesis outcome. Modifications to the synthesis scheme reported in the literature will be evaluated and incorporated as appropriate.

Outlook

This work will have the immediate impact of accelerating the research of the many UCLA labs investigating the [18F]FAC class of PET tracers. The outcome of this research may be translation of this tracer into a clinical imaging agent.

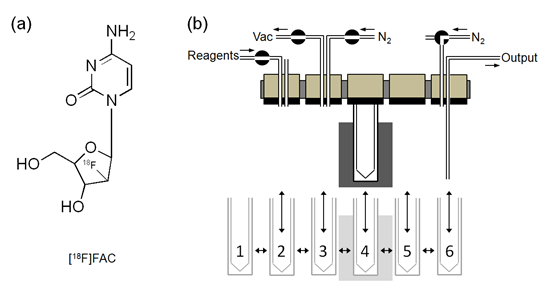

Figure: (a) Structure of [F-18]FAC. (b) Schematic of one of the three robotic reactor susbsystems in the automated synthesis platform.

van Dam, Keng, Sadeghi

Background

The use of small volumes and microdevices are attractive for the production of PET tracers due to the potential to increase specific activity, increase yields and shorten synthesis times, reduce precursor consumption, and reduce the infrastructure/equipment needed to synthesize tracers. While several advances have been made in platforms for radiochemical synthesis, this has not been the case for the quality control analysis of the produced compounds nor their purification. In particular, most PET tracers require HPLC purification using expensive and bulky equipment. The use of such equipment negates the advantages of the compact and simple nature of microfluidics. Several on-chip analytical methods have been developed for separations, including capillary electrophoresis (CE), HPLC, capillary electrochromatography (CEC), etc. that may be applicable for PET tracer separation.

Methods

Relative abundance of species expected within a crude radiochemical preparation will be analyzed. Existing on-chip separation methods and on-chip detection methods reported in the analytical chemistry literature will be compared to determine the most promising approach(es) for separation and detection of the desired tracers from the crude mixtures. A proof-of-concept testbed will be developed based on commercially available equipment and chips to determine feasibility of the proposed separations. If successful, the techniques will be integrated into a microfluidic chip and coupled with the radiosynthesis chip for full-miniaturized PET tracer synthesis.

Outlook

Integration of the purification process represents one of the final hurdles in miniaturization of new technology for PET tracer production. Addressing this missing link will have wide-ranging impact in PET radiochemistry and enable a shift from centralized to decentralized production of tracers for greater diversity and accessibility of tracers.

Keng, van Dam, Kim

Background

Over the past years, microfluidic technologies have demonstrated much potential and advantages for PET radiosynthesis. To date, state-of-the-art microfluidic platforms have been adapting conventional macroscale radiosynthesis methods, which generally involved high temperature synthesis, the use of harsh reagent, reaction and evaporation processes are performed under inert conditions. Furthermore, conventional radiosynthesis methods are optimized with large excess of precursor to achieve >60% yield, which necessitate purification by HPLC. The need of complex purification instrumentation and specialized personnel inhibits development of microfluidic radiosynthesizer to be used at imaging clinics and research institution. To realize a compact, easy to use and robust microfluidic radiosynthesizer for on-demand PET probe production, a cleaner radiosynthetic strategy with integrated on-chip purification platform are critical toward facilitating on-chip PET probes production. To overcome these challenges, solid phase support synthesis is particularly attractive in radiochemistry because large excess of precursor is typically used to drive the reaction forward, which complicates the final purification. By embedding precursor on the solid phase using a nucleophilic cleavage linker, only the fluorinated product is collected while other by-products and unreacted starting material remained on the solid phase, thus could potentially simplify purification via solid phase extraction on-chip.

Methods

We will first design an activated solid phase linker strategies with high selectivity towards nucleophilic fluorination cleavage. The solid phase linker will consist of an optimal (1) linker length, (2) leaving group that is alkylated to a desirable PET probe precursor, (3) electronic and steric contributions at the substitution site to achieve the highest fluorination efficiency while hindering the formation of by-products. Similarly, suitable functional polymers for extracting impurities that are liberated from a typical radiosynthesis will be investigate to possess optimal hydrodynamic flow, surface area, functionalities, extraction efficiency and product recovery.

Outlook

The development of a universal solid phase radiolabeling and purification platforms will overcome fundamental challenges in radiosynthesis, and thus could empower biologists to discover new diseases, probes, diagnostics, treatments and drugs via PET molecular imaging.